TAURUS rail system, the perfect fall protection system for all types of modern facades

Specialist series: Fall protection for facades

7 tips on installing concealed fall protection systems on façades, with or without rope access technology

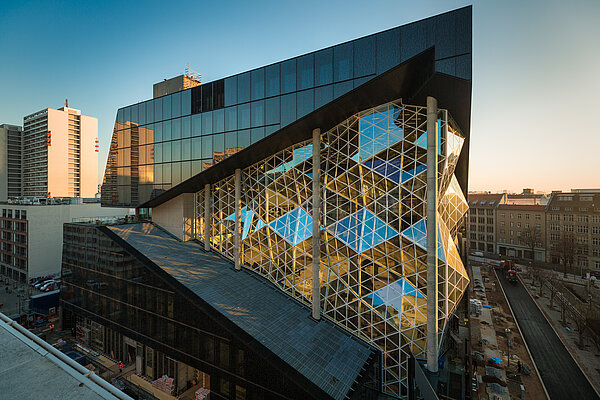

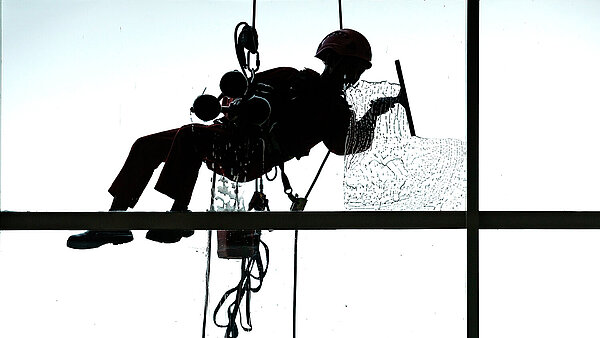

Safety systems should not spoil the aesthetics of the façade. Nevertheless, they are important for maintenance & cleaning. The imposing glass structure was in the spotlight when it was time for cleaning the windows, because nobody had thought about the fall protection system required for this on the building’s unusual façade. So that you avoid being confronted with exactly this challenge, we have put together 7 tips for concealed fall protection and rope access technology.

Correct planning and implementation of rope access technology on facades

Fall protection with rope access technology is an ideal solution for facades if they are also planned in good time. Architects increasingly decide to install rope access technology. The best way to integrate the rope access technology seamlessly into the building structures is to factor it in at the planning stage. The challenges arising during planning and implementation and the mistakes to avoid are summarised below.

Holistic rescue concept for facades

After a fall every minute counts. Of course, the goal must be to avoid accidents through even better planning, equipment and training. If accidents do happen, rescue measures must be professionally prepared in order to keep the consequences as low as possible. One missing link to the rescue chain can lead to serious injuries and death. In this article you will learn how rescue concepts are prepared in connection with facade work and how rescue measures are to be carried out in an emergency.

What is rope access technology and what are its benefits for facades?

Safety & beauty on facades - no problem with rope access technology. Because of very differing facade types, a safety system is required with which the user can reach otherwise inaccessible locations for cleaning and servicing tasks. This is particularly where the illusion of safety occurs more quickly than most people would like. Thanks to its great flexibility and high safety standards, one process which currently enjoys favour is rope access technology. In this article, we explain to you the concept and its benefits.

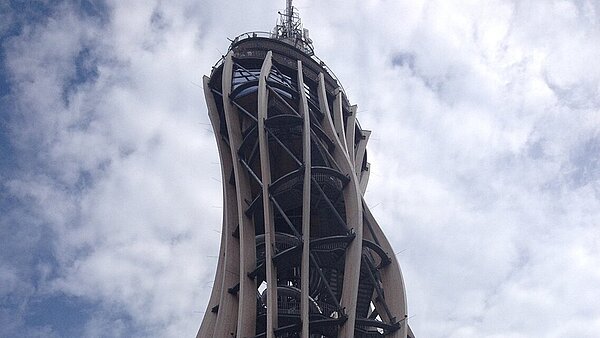

5 modern facade types on which rope access technology is possible

Facades differ greatly. Every facade is unique and has its own special requirements in terms of safety, because each building shell must be cared for, serviced and, where necessary, repaired. In order to avoid the illusion of safety, a sustainable safety concept is therefore absolutely essential. In this blog, we would like to introduce to you 5 facade types where we have already gained experience in the past and were able to apply fall protection using rope access technology.

A day’s work in rope access technology for facades

Safety is created above all through the correct workflow. Since 2019 rope access technology has been officially registered in TRBS 2121 as authorised working equipment. It is a rope-supported access process for installation, cleaning, and service tasks on facades. A debriefing and analysis takes place afterwards. In our blog, we’d like to show you this chronology for the individual steps of rope access technology, and to explain each of them briefly.

Rope access technology on facades - all information at a glance

Definition, benefits, system, processes, legal foundations & more. Buildings are becoming higher, more modern, more complex, more spacious... The safety technology for working at height on these buildings must be correspondingly well-developed and flexible. This is why agile and dynamic rope access technology is being used with increasing frequency. It provides optimum fusing of aesthetics and safety on facades, and simultaneously provides the users with maximum flexibility when performing facade tasks such as cleaning, servicing, or repairs.

All-round protection on facades with the (S)TOP application principle

Industrial safety on facades is essential. Dangerous behaviour in the workplace must be avoided under all circumstances. In our example, the solution would be suitable fall protection for cleaning the ceiling-high window. Ideally, risks are already eliminated in advance,e.g. by means of correct workflows. We now consider, in terms of facade safety systems, what the acronym (S)TOP represents and what lies behind it.

7 steps of risk assessment of facades

Tasks on facades harbour risks which have to be minimised. Safety concepts for risks of falling from facades, on roofs, and also in industry have been our special field since 2001. Facade safety is an especially exciting area, because there are an incredible number of different facade types, each with its very own requirements.

How To Achieve the Optimal Invitation to Tender for Facade Protection

Our experts share their best tips. The earlier the technical advice and planning for facade protection takes place, the better you’ll have your costs under control and the more successful you’ll be in the tendering process. Discover our 3 professional tips for this.

Fall Protection for Facades: How Much Does it Cost?

All cost items at a glance. Roland K. opens the envelope and pulls out a multi-page stack of paper, and his heart almost stops. The offer for securing the facade of his current construction project is much higher than he’d previously calculated in the tender. Our architect Roland K. here could have avoided this sinking feeling that comes with discovering unanticipated costs. Because with good and early planning, cost-effective solutions for fall protection on your facade can be found. Read on and find out what the costs are made up of, and how you can plan and implement facade security in a way that will save you money.

Whoops, facade safety forgotten – what can be done?

Necessary steps & expert tips that work. Inclusion of an experienced expert for facade safety early in the project pays for itself in the end, through appropriate know-how and attractive cost benefit advantages. And even if the fall protection system has been forgotten, a partner like this usually has a final ace up his sleeve.

Fall protection on facades: 2 best practice examples

Stylishly matched to the project’s architecture. For every fall protection system, the focus is on saving lives. A holistic, sustainable safety concept for the facade safety system is the best possible gain for construction projects. At the same time, the safety system should integrate into the overall concept of the building, and complement the architecture. Discover two best practice examples for façade protection below.

High-level view of fall protection on facades

Fall protection on facades needs to be stylish and safe. Every year, hundreds of people suffer accidents on roofs, facades, and other workplaces at height. The shockingly high number of such accidents could be reduced if suitable fall protection systems were in use. However, at the same time the facade safety system should not detract from the beauty of the building, because every structure has its own aesthetic value.

Even very modern facades also need fall protection

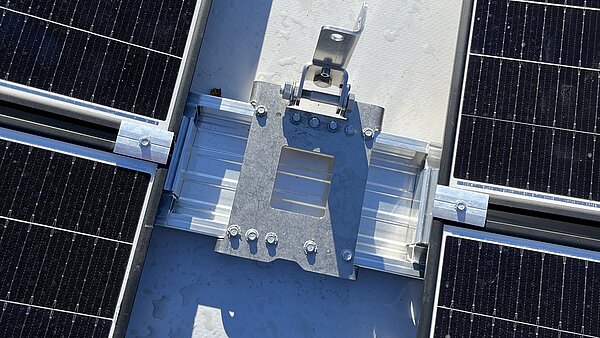

Time to travel new paths. That’s the motto of Lobster Data GmbH in Tutzing (Bavaria). But it’s not just as a software provider that Lobster puts its faith in developing and selling highly innovative solutions. Recently the company management decided to travel new paths in terms of safety too.

Safety at dizzying heights: TAURUS from INNOTECH as fall protection for the MED CAMPUS Linz

The building’s modern, aesthetic facade, designed by the LORENZATELIERS architectural practice, obviously has to be cleaned and maintained regularly. So that these cleaning and maintenance tasks on the external components of the facade, plus the window and glass elements, were made as safe as possible, those responsible decided on a TAURUS professional fall protection system.

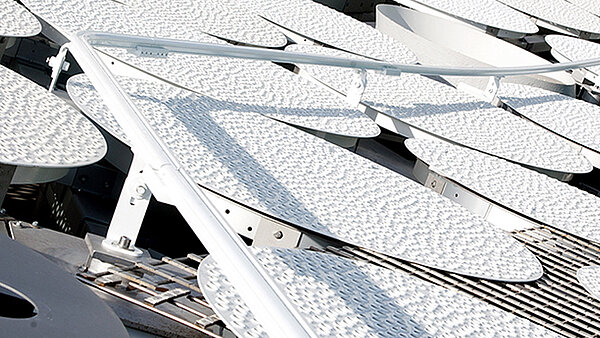

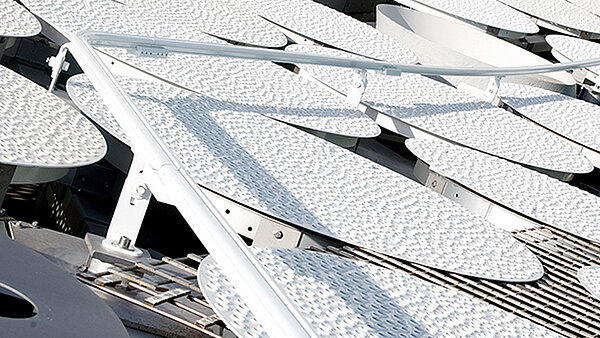

TAURUS rail system, the perfect fall protection system for all types of modern facades

Regardless of the facade type, the topic of safety is always of decisive importance. Especially for intelligent facades which adapt to different weather conditions and to the actual position of the sun, regular servicing and cleaning is always necessary. Find out in this post how TAURUS is the optimum solution as fall protection for facades.

![[Translate to Englisch:] CEO Christoph Reiter, MSC [Translate to Englisch:] CEO Christoph Reiter, MSC](https://www.innotech-safety.com/fileadmin/_processed_/8/1/csm_christoph-reiter_acbe8eb004.jpg)

![[Translate to Englisch:] PV system with fall protection](https://www.innotech-safety.com/fileadmin/_processed_/1/a/csm_IMG_0028_49912f54f1.jpeg)

![[Translate to Englisch:] Flat roof protection with the AIO](https://www.innotech-safety.com/fileadmin/_processed_/4/7/csm_IMG_5568_e356e1ebd2.jpeg)

![[Translate to Englisch:] [Translate to Englisch:]](https://www.innotech-safety.com/fileadmin/_processed_/1/a/csm_Mehrere_PV-Kunden_gleichzeitig_betreuen__kann_oft_zur_Riesenherausforderung_werden-header_3016356278.jpg)