Roof penetrations are frequently used for the installation of solar systems or other roof-mounted systems. They make it possible to connect such systems to the roof, securely and without leaks. A roof penetration is an opening made through the roof covering in order to mount components such as roof windows or solar systems.

The implementation of connections through roof penetrations requires careful planning, and compliance with specific requirements. Proper sealing between the roof penetration and the roof surface is decisive in preventing the penetration of water and the risk of damage. Information sheets and guidelines provide information about the selection and installation of the correct components, such as sealing materials or connecting clamps when attaching via roof penetrations.

Different elements are designated as roof penetrations or installation components. These include, for example, installation elements which penetrate, rainproof connections, and flexible inclination brackets. These components ensure a secure connection between the systems and the roof, protect the roof from damage, and create an effective installation.

Correct execution of roof penetrations is decisive in minimising risks such as leaks or roof damage. It is important to take all necessary measures to protect the roof and to ensure the long-term functioning of the system.

What are the risks of a roof penetration, and can they be avoided?

A roof penetration harbours certain risks, especially the potential risk of leaks and damage to the roof structure. Leaks can occur when the seal between the roof penetration and the roof surface is not made correctly. This can create serious problems, such as water ingress into the building, structural damage, and mould growth.

Potential damage can also be caused when executing the roof penetrations. For example, old or damaged roof tiles can be (further) damaged during an installation process, and this can result in leak points. Equally, if performed incorrectly, sealing the roof penetration can create insufficient protection, and thus increase the risk of water ingress.

To minimise the risk of leaks and structural damage, certain measures need to be taken.

- Firstly, before performing the roof penetrations, it is important to thoroughly investigate and assess the roof structure, in order to determine whether it is suitable for this purpose.

- It is advisable to use high-quality sealing materials, and to apply these correctly.

- Regular maintenance and inspections of the roof are also important for recognising potential damage, and correcting it in good time.

Some roof types are better suited for roof penetrations than others. Flat roofs often provide a more advantageous platform for roof-penetrating installation, while pitched roofs may require additional structural modifications. A comprehensive inspection of the roof structure is therefore essential, in order to identify potential risks and challenges, and to find suitable solutions.

Overall, careful planning, selection of high-quality components, and correct execution of the roof penetrations, plus regular maintenance and inspections are decisive in minimising the risk of leaks and damage. The proper sealing of roof penetrations is of fundamental importance for ensuring long-term functioning and roof integrity.

BARRIER-VARIO

Guardrail system with weights as superimposed load

The BARRIER-VARIO guardrail system is used wherever the fall edges of a flat roof up to a maximum pitch of 10° must be protected. The guardrail held in place by superimposed concrete weights creates a barrier around the fall-risk area, and thus ...

BARRIER-FLEECE

Guardrail system with green roof as superimposed load

The BARRIER FLEECE guardrail system is used wherever the fall edges of flat roofs up to 10° inclination must be protected. It creates a barrier to the fall edge, and so all persons located on the roof can move about in safety. This system is ...

BARRIER-SKYLIGHT

Guardrail system around skylights/strip lights

The BARRIER SKYLIGHT guardrail system is used wherever skylights must be protected on roofs of up to 10° inclination. Regardless of the size of the skylight, the superimposed load system provides optimum fall protection, and thereby neutralises ...

Are there fall protection systems not requiring roof penetration?

The installation of fall protection systems on roofs is of decisive importance for ensuring the safety of people who perform work on roofs. A frequently-asked, important question is whether fall protection systems without roof penetration are possible. Because roof penetrations can increase the risk of leaks and structural damage, many people look for alternatives which avoid this.

The good news is that there are indeed fall protection systems which do not require roof penetration. This type of fall protection system is generally referred to as a free-standing fall protection system, and such a system can be installed on a roof without having to drill holes in the roof covering. Normally these systems are held down by ballast weights or other stable holders, and they provide a safe working area for roof workers, without creating the risk of roof damage.

These free-standing fall protection systems are a favoured alternative where roof penetration is not desirable or possible. They provide the same safety and protection as normal systems without having to bore through the roof, thus ensuring the integrity of the roof structure.

All in all, fall protection systems without roof penetration can be said to provide an effective option for ensuring safety on a roof, while simultaneously avoiding potential damage.

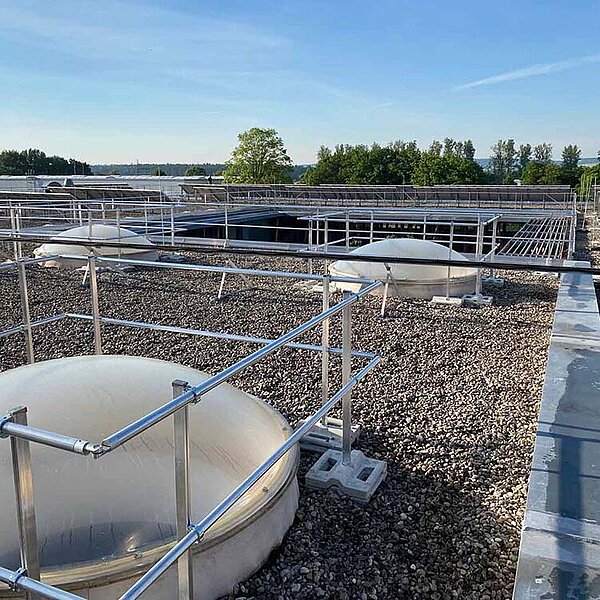

Practical example: Guardrails without roof penetration

A practical example of how a guardrail can be installed without roof penetration is the use of free-standing guardrail systems. Instead of attaching the guardrail by penetrating all the way through the roof, the system is set up without direct connection to the roof, and is secured by suitable ballast weights or brackets.

The advantages of this method of installation:

- Firstly, it creates a safe working environment for roof workers, without having to bore through the roof. This reduces the risk of roof damage and leaks.

- Secondly, the integrity and durability of the roof structure remain intact, because no holes are drilled into the roof covering. This extends the roof’s working life and minimises potential repair costs.

A number of risks can be avoided by installing guardrails and avoiding roof penetrations. These include the risk of leaks, structural damage, material wear, and the potential impairment of the roof’s overall aesthetic impact.

![[Translate to Englisch:] [Translate to Englisch:]](https://www.innotech-safety.com/fileadmin/_processed_/9/a/csm_dachdurchdringung-gelaender-lichtkuppel_193b04de57.jpg)

![[Translate to Englisch:] PV system with fall protection](https://www.innotech-safety.com/fileadmin/_processed_/1/a/csm_IMG_0028_aa4a4efcbb.jpeg)