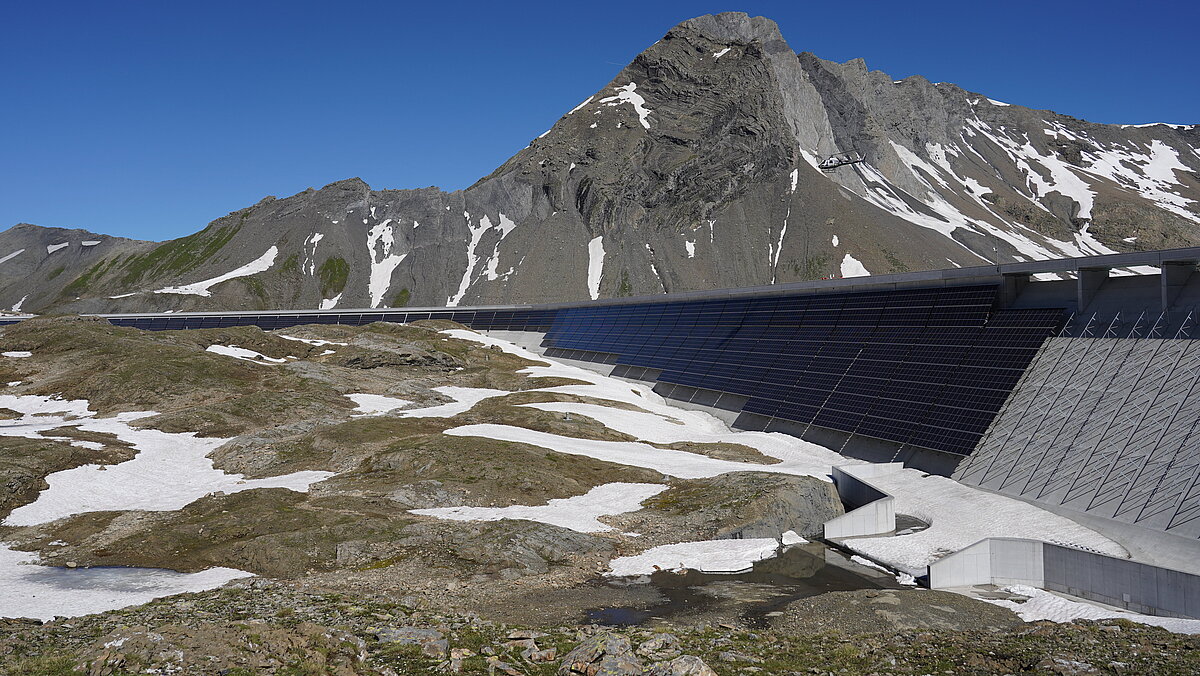

Last year, the operators decided to exploit this highly exposed location for further possibilities of energy production. This decision gave rise to the idea of creating the largest and highest solar power plant in Switzerland, an Alpine solar installation. This idea was quickly put into practice - under the name AlpinSolar.

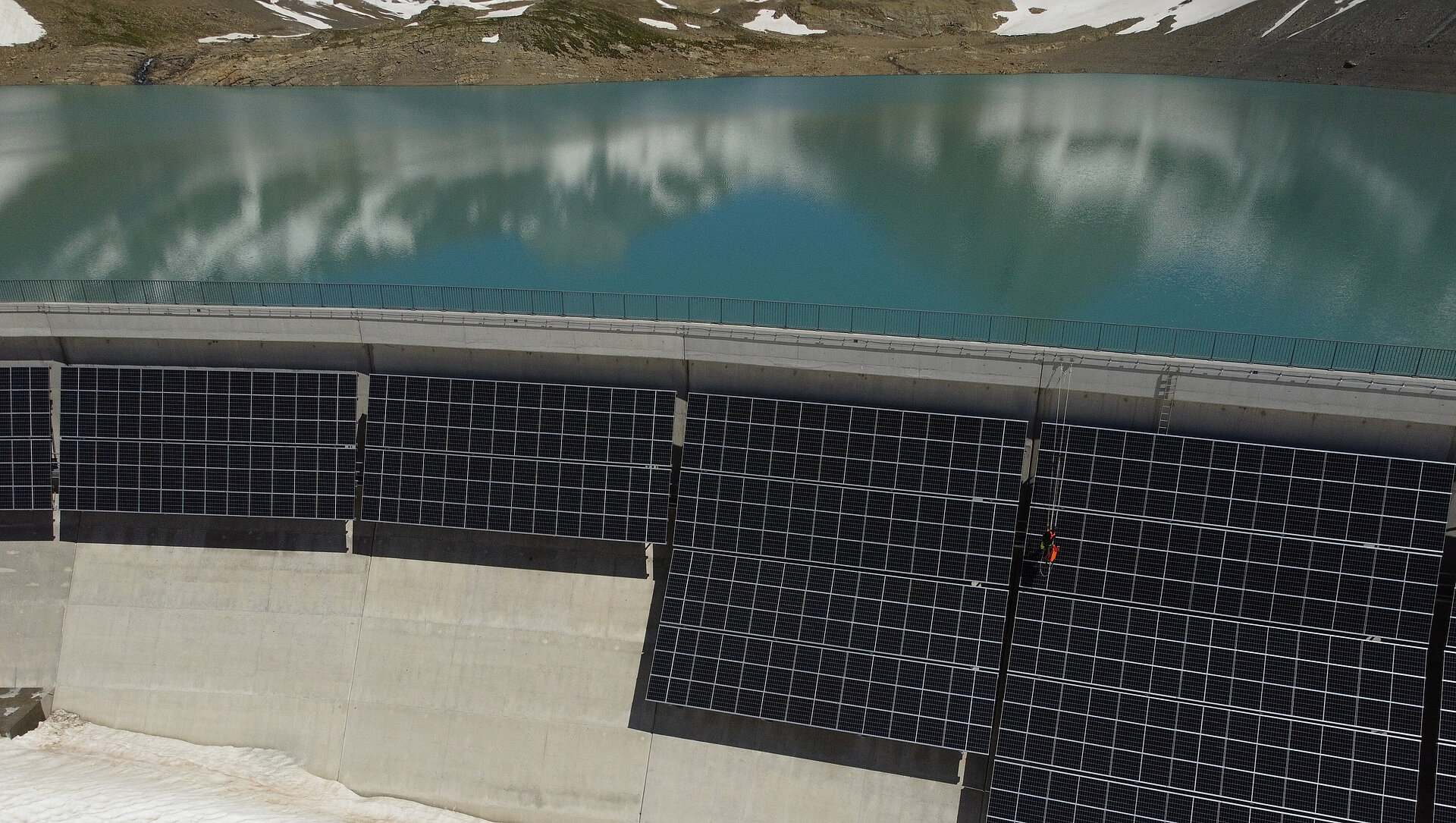

For this purpose, the entire dam was equipped with solar panels and is now taking another new step in the transition to renewable energy. Under ideal conditions, Alpin Solar is supposed to feed 2.2 megawatts of power into the grid and generate climate-friendly electricity in the realm of 3.3 million kilowatt hours.

The challenge was enormous. But, ultimately, the project is likely to become a huge success, as a solar power plant above the fog line is hit by the rays of the sun with much greater intensity than, for instance, an installation on the plains. The surrounding snow gives an additional boost to these positive effects by reflecting the sunlight. Better still, the lower temperatures found at higher altitudes also significantly improve the efficiency of a solar power plant.

These factors combined allow the installation on Lake Mutt to make optimal use of the energy of the sun and generate a maximum amount of electricity. A forward-looking project, as it paves the way for other power plants that could theoretically harness the power of both the water and the sun in the same way for the purpose of energy generation. Naturally, the photovoltaic modules called for a professional and reliable safety solution - not only for assembly, but also for ongoing and regular maintenance as well as cleaning.

Significant challenges resolved

As can be imagined, the site's location at its tremendous altitude in the middle of the Alps severely limits the options for traffic and transport. Adding to the challenge of working in such a lofty mountain region is the fact that the air at such elevations contains roughly 25% less oxygen. These adverse conditions added up to a daunting challenge - both in terms of the logistical and the physical requirements. As an example, the majority of the transport trips had to be made with a helicopter.

In light of these conditions, particular importance had to be attached to the aspect of safety. For the installation of the PV modules as well as for all further work, the operators of the Lake Mutt hydropower plant were trying to find a fall protection system that is extremely user-friendly, i.e. easy to use, but also easy to install, while being able to stand up to the extreme Alpine weather conditions in the best possible way.

High requirements...

“Since the installation will remain in operation for decades, we needed to provide proof beforehand that every anchor, every connection and every bolt was in compliance with the strict requirements for working freely suspended from a rope”, details Christian Paoli, Managing Director of Secureco AG.

Another challenge was that the lowest part of the dam wall had to remain clear, as there is a small glacier on the ground that could have destroyed the solar panels. In addition, the solar power plant had to be mounted on the wall in such a way that an inspection of the dam itself by Switzerland's dam supervision authority was possible at any time. Last, but not least, the task of obtaining all the necessary permits for this pioneering construction project was colossal at times.

Facts and figures

A project of this magnitude also requires scores of components and materials. To allow for the generation of renewable electricity, the building of the Alpine plant consumed a total of 5,000 PV modules with the associated accessories for installation on the dam wall of Lake Mutt. The components had to be transported by helicopter. However, those transport flights could only be made in suitable weather. And, the weather was not always cooperating.

Adverse weather conditions often brought the work to a temporary halt or standstill. For the entire duration of their assembly work on the installation/the fall protection system, the team was housed in mobile homes or in a hut provided by the Swiss Alpine Club, SAC.

The solution

For everyone involved, including Christian Paoli, who is in charge of the safety concept, AlpinSolar was an absolute first. “We never had to master a construction site of similar magnitude and had to put a tremendous amount of thought into such aspects as the surroundings, planning and implementation“, declares Christian Paoli, looking back on the project. In addition, Paoli and his team only had a time window of 4 weeks to install the fall protection system.

Due to this time restriction, the system had to be fast and easy to install - in addition to offering perfect safety. This is why Paoli opted for the TAURUS rail system made by INNOTECH. The aluminium rails of this safety solution are very robust and can be adapted perfectly to a variety of structures. Better yet, enduring high temperature fluctuations, as they sometimes occur in the mountains, is an absolute cinch for the TAURUS thanks to its special properties.

Since this solution is also certified for the rope access method, it was Paoli’s first choice. The special properties of the system allowed the PV installers to attach every single panel to the dam wall with pinpoint precision.

A total of 915 metres of TAURUS rails were installed for the fall protection system of the AlpinSolar project on Lake Mutt. This added up to a total of 305 rail elements. In addition, installation required 696 TAURUS-BEF-30 and 219 TAURUS-BEF-30 fastening angles as well as 108 rail connectors (60 TAURUS-VB-11 and 48 TAURUS-VB-10-VE5) plus a great number of other elements and components.

By loading this video, you accept Google's privacy policy.

Now that the AlpinSolar project is complete, Paoli is highly satisfied and attributes this success to the long-standing and close cooperation with INNOTECH. He speaks particularly highly of the end-to-end documentation, the certifications and the continuous advice provided by INNOTECH. Another person who is just as proud is Curdin Erne from INNOTECH: “The installation of the PV system would not even have been possible without our fall protection system.“

“We have certainly completed quite a few extensive and impressive commissions with the TAURUS rail. However, the Alpine installation on the dam wall of Lake Mutt is the largest project to date for which we implemented this system”, rejoices Christoph Ortner, Head of Corporate Sales at INNOTECH.

Summary

The hydropower plant with its PV installation clearly illustrates that even highly exposed solar power plants can be optimally secured. In addition, this dual use of hydropower and solar energy is enormously important when it comes to actually making electricity generation green in the future. Even if the challenges at the beginning of such projects may seem overwhelming, the AlpinSolar we see today embodies a highly effective solar power plant that would not exist without the pioneering spirit of the operators of the hydropower plant on Lake Mutt. This ground-breaking project has shown that it is possible to work safely even in high Alpine elevations.

More details on securing hydropower plants can be discovered in our free tip sheet.